I haven't been sitting idle, but I think I can accurately say that I haven't accomplished anything either.

I designed the car well in CAD. My thought was to 2.5d manufacture it with Balsa. I got some thin strips of Balsa wood from a local model airplane shop.

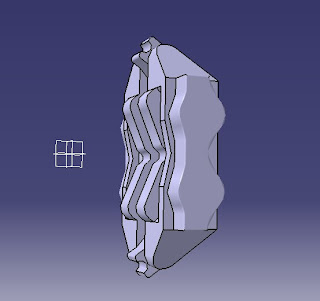

First, I sectioned my CAD model every 0.5 mm.

Then I printed the shapes

Cut a form out

Cut some tape

Tape the cut out image onto the balsa wood

Drilled a couple of alignment holes

Holes now drilled

Used a razor blade to trace the image on the paper onto the balsa.

Paper is now cut.

Take the taped paper off

Use the razor to cut the image all the way out of the balsa.

Remove the balsa section

Placed on the guide pins.

Repeat. A lot. Stacked all the balsa sections up. Epoxied them together, and covered the whole thing in a thin coat of wax.

Here are my attempts. My "try again" garage.

In the end, this didn't work either. Problem is, when you stack up 96 pieces of .5mm balsa, it doesn't necessarily make a 48mm part. I was counting on the balsa being exact, and I think at that thickness, it's just too much to ask. My first model was too tall, my second attempt was too short. Anyway, I gave up 2.5d prototyping, and tried to make a tool from my balsa blank. I mixed the plaster with too much water, the plaster tool was too soft, and broke when I tried to reassemble it to pour a casting. I'm done. I'm done with doing this by hand, I'm done with plaster casting.

I'm going digital.

Total: 194 h