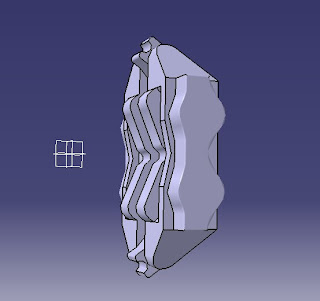

I have essentially completed the front upright

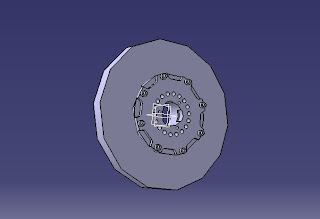

The upright as pictured above includes the brake duct. Here is the brake ducting completed as a separate part.

I haven't had a lot going on at work lately. I was searching for aftermarked parts for my current project (http://jordan191model.blogspot.com/) and found these tires made by Wolf Design on the Media Mix Hobby website out of Singapore (click here).

If you compare the above photo of the 1/20 scale part with the below picture of a Goodyear tire on a 1993 McLaren, the realism is supurb.

The availability of these tires is a game changer for me. Up to this point, I have been planning to design the whole car in CAD, get something like this, convert it to a CNC mill, design molds from my CAD parts, convert to G-Code, mill the molds, and resin cast the parts, use RTV rubber for the tires. I still believe that this method should be effective in general, but observing the detail on these tires by Wold Design, I can't figure out how I would repoduce such detail. Imagine the size of the drill bit I would have to put into the CNC mill to get this kind of detail. It's hard for me to believe that while milling metal a drill bit that small wouldn't break.

At present, I am now planning to buy a set of these tires and use them on the kit. They cost $31.74 including shipping to Poland, and to be honest, I don't think that I can match their level of accuracy for that price, at least until I have a bit of milling experience. The monocoque is a different story, for one because a model of this car is not available and must be prototyped, and for two, it doesn't involve the incredible level of surface recessing that these tires have.

This has serious implications for the work I've done so far. I have designed everything around the concept of 13 in scale wheels, in other words wheels that have a 16.5 mm diameter. The wheels I have designed will not fit for example into the Tamaya Jordan 191 tires, as the wheels in that kit have a slightly larger diameter. As I don't currently possess these Wold Design Tires, I don't know what their inner diameter is, and can't really design wheels until I do know. Furthermore, the size of the brakes/calipers/uprights/brake ducts is dependent on the inner diameter of the wheels for clearance purposes, so they are all designed thinking the outer diameter of the wheels would be 16.5 mm. If it is even a 0.5mm different, it changes all the design parameters. As such, it's back to the drawing board again. I've learned a lot about how do draw in CAD, the possibilities/limitations of different CAD programs, and this has been very beneficial. Considering the new tire possibilities, I think it's best for me to set this aside and begin working on another part of the car. That probably means it's back to the front wing/nose/monocoque/sidepods/undertray/cowling.

Total time: 230 h