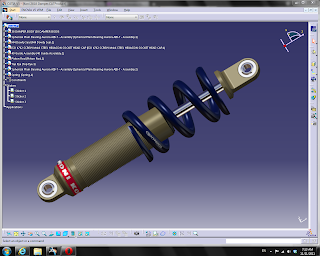

I've now got a spring that I'm satisfied with for the time being. This is all a work in progress, where a lot of adjustment will be needed to fit the damper to the car at a later point.

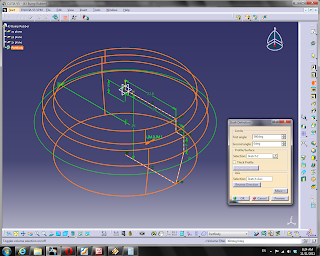

Hmm, that looks way more complicated than it actually is

Shaft

Paint black

Fillet

Put into assembly and make adjustments as need to get everything to fit right.

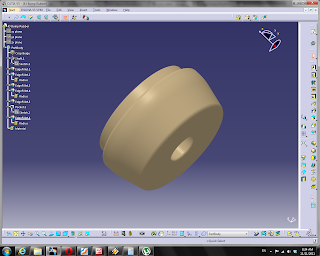

Bump Rubber

Shaft

Pocket a hole in the center for the piston rod and fillet

Apply material

Insert into assembly

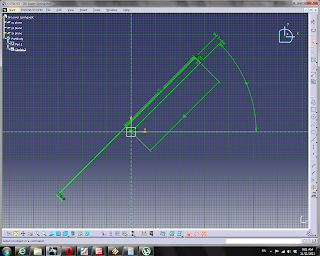

All that's really left for this mock up is the lower spring seat. This is going to be a bit more fun.

First a 1cm pad of just over a 3" circle (2" id spring with 1/2" wire)

Now we want to make 8x 6mm holes in the side of this

So the point of this drawing is that the axis of the hole is an angle from the origin, change the angle, and the hole moves. The 3mm measurement is the radius of the hole we want to create.

Mirror this, so we can do both sides at once

Groove

Copy sketch, adjust angle, repeat

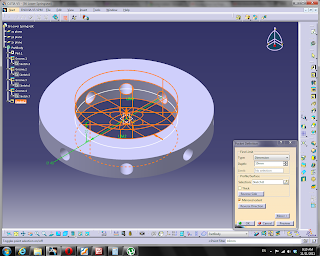

Eventually, you wind up with a disk with a bunch of adjustment holes in it

So this thing needs to fit a 45 mm shaft

Add a cylider to this (based on my reference photos)

Now let's cut some weight out of it. Neat thing about working with circles, is you only need to design the stuff once, and then mirror, mirror, mirror our way around the circle.

Fillet the crap out of it and paint it black.

Put into assembly

Realize your bump rubber is way too big. Change it. Might as well add a groove while I'm at it.

I think I'm pretty much satisfied with that

Sunday, November 20, 2011

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment